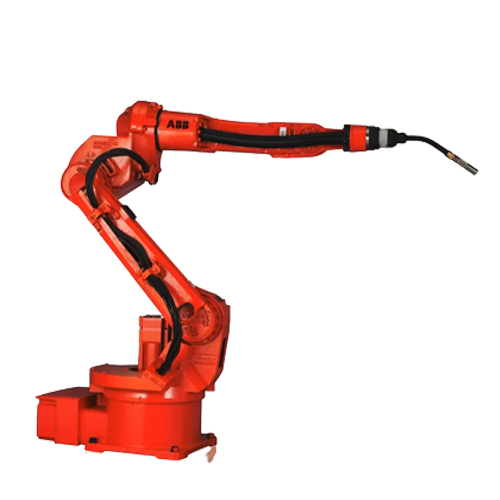

Description

Pressure Handle

The pressure handle is typically located on the welding torch or in close proximity to the welding area, allowing the operator to easily adjust and regulate the pressure applied during welding. It is designed to be ergonomic and easy to grip, enabling precise control over the pressure exerted on the workpiece.

During the welding process, the pressure handle is utilized in conjunction with other welding parameters, such as current, voltage, and welding speed, to achieve optimal results. The operator adjusts the pressure handle according to the thickness and type of materials being welded, as well as the desired welding specifications.

Proper pressure control is essential in welding as it directly affects the quality and integrity of the weld joint. Insufficient pressure may result in inadequate fusion, leading to weak or incomplete welds. On the other hand, excessive pressure can cause deformation, distortion, or even damage to the workpiece, compromising the structural integrity of the weld.

In addition to controlling pressure, some advanced welding machines or torches may also incorporate features such as pressure monitoring and feedback mechanisms. These systems provide real-time information to the operator, enabling them to maintain consistent pressure throughout the welding process.

Overall, the pressure handle in welding plays a crucial role in achieving high-quality welds by allowing operators to precisely control the pressure applied during the welding process. By ensuring proper pressure application, welders can achieve strong and reliable weld joints, meeting the required standards for various applications in industries such as manufacturing, construction, automotive, and aerospace.